Analyzer, EasyViewer 400

View and Measure Particles in Real Time.EasyViewer 400 System Configuration

New Experimental Insights

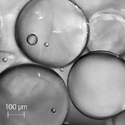

Capture high-resolution images of particles as they exist in situ, at previously unobtainable levels of detail, to reveal new insights for processes.

Powerful Analytics

Transform EasyViewer into a powerful particle size and shape analyzer using optional image analysis methods in iC Vision to design particles faster.

Flexibility for Scale-Up

Compare results from small scale to larger scale during transfer to de-risk late stage process development.

Material No.: 14000220

Real Time Analysis

Powerful analytics allows process monitoring or particle determination with integrated software.

Introducing EasyViewer 400

Characterize particle processes across scales, supporting process scale-up, transfer and production.

| Probe Wetted Material | Hastelloy C22 |

| Probe Window Material | Sapphire |

| Probe Wetted Temperature Range | -80 to 100°C (purged) 10 to 100°C (standard) |

| Probe Back End Temperature Range | 0 °C – 25 °C |

| Probe Wetted Pressure Range | 0 bar (full vacuum) to 10 barg (Standard) up to 100 barg (custom) |

| Certifications | CE/NRTL Approved, Class 1 Laser Device, Compliant with 21CFR1040.10 and 1040.11 and IEC 60825-1 |

| For Use In | Non-Hazardous Lab or Plant |

| Software | iC Vision |

| Imaging System | Front Lasers: Backscattered images Back Lasers: Transmission images with use of optional clamp-on reflector |

| Illumination | Back Lasers: 4 Front Lasers: 4 |

| Probe Window Seals | Teflon O-Ring |

| Probe Diameter | 19mm |

| Probe Wetted Length | 400mm |

| Conduit Length | 3m [9.8ft] |

| Field of View | 1100 μm x 800 μm (± 50 μm) |

| Optical Resolution | > 980 nm |

| Image Resolution | 2200 x 1700 pixels |

| Weight (probe, interface unit and cables) | 1.45 kg [3.20 lb] |

| Air Requirements | Always use clean, dry instrument quality air or Nitrogen Low flow purge (optional, use to avoid condensation), 1.4 barg [20 psig], 0.5 SLPM [0.02 SCFM] |

| Power Requirements | Via USB 3.0 on control pc +5 VDC, 1.7 A (maximum) Via USB 3.0 powered extender 100-240 VAC (auto-switching), 50/60 Hz, 1.7 A |

| Laser Wavelength | 450nm |

New Experimental Insights

Capture high-resolution images of particles in situ to obtain deep process understanding for complex systems. Study crystallizations, suspensions and emulsions in previously unobtainable detail and reveal new insights that will power process-development.

Powerful Analytics

Transform EasyViewer into a powerful particle size and shape analyzer using optional image analysis methods in iC Vision. Monitor process changes or quantify particle size and shape with custom algorithms. Use images to verify results. Design particles faster.

Flexibility for Scale-Up

The small, probe-only instrument design and flexible mounting system can be inserted into reactors, pilot vessels and pipelines. Results from smaller scales can be compared to results from scale-up, de-risking late stage development.

Confident Deployment

Leverage auto-focus, auto-lighting, and auto-save-best-image software features to ensure every project team member can collect the highest quality images from the beginning to the end of every experiment, so that you never miss anything.