Forklift Scale VFS120 ETO

Safe, Reliable, and Easy to Use.The VFS120 forklift scale weighs pallets anytime and anywhere. Optimize your transportation line and workflow, decrease forklift power consumption and bring higher productivity to freight, logistics, warehouse, and shipping environments.

Angular Compensation Technology

Angular sensor with anti-vibration functionality combined with a dedicated algorithm that compensates for uneven surfaces, maintaining weighing accuracy.

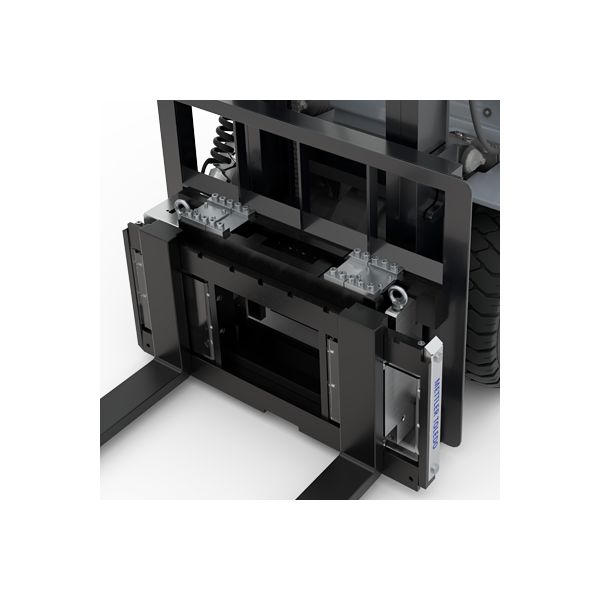

Eccentric Adjustment Function

Two load cells inside the weighing carriage balance the load from side to side. The flexure design keeps the load balanced from back to front.

High Visibility Windows

The VFS120 provides superior visbility through open windows in the middle and sides of the weighing carriage for increased driver safety.

Material No.: 30584557

| MaximumCapacity | 3,000 lb - 10,000 lb (1,500 kg - 5,000 kg) |

| Width of Carriage | 762 mm - 1,250 mm |

| Installation Class | II, III, IV |

| Load Loss Distance | 6.5 in 6.9 in (165 mm 175 mm) |

| Resolution | 2 lb 5 lb 10 lb (1 kg 2 kg 5 kg) |

| Connections | DB9 cable or a Bluetooth dongle |

| Certificated temperature | '-10 C to 40 °C 14 to 104°F |

| Material | Steel |

| Capacity Loss | ~15% of forklift capacity |

| Angular Compensation Range | Pitch ±5°, Roll ±3° |

| Load Cell | TSH Loadcells |

| Safe Overload | 150% |

| Stable Weighing Time | 1-2 seconds |

Cut maintenance costs in half

Unique 3-point suspension holds calibration for 12 months, meaning no need for regular scheduled service. Robust design reduces the need for unplanned service and repair.

Accuracy in all conditions

For use in the rough LTL industry, the VFS120 delivers accurate weighing results, even in tough conditions.