With the V15 Round Line, manufacturers get an efficient inspection process that reduces the risk of expensive and brand-damaging product recalls. The system uses six vision sensors to confirm the presence, completeness and readability of alphanumeric label information and printed 1D and 2D codes by generating images of the complete label surface with minimal distortion

Advantages of Machine Vision Inspection

Increase efficiency, reduce waste and avoid recalls

An Easy Entry into Machine Vision Inspection

Take Control of Your Package Quality

Adding a machine vision inspection program brings numerous advantages to the production process, particularly where efficiency is concerned. Vision inspection's ability to closely inspect each product means manufacturers obtain greater peace of mind knowing that no product will leave the facility unless it is looking its best. This acts as an additional layer of brand protection, helps to minimize rework, mitigate the risk of certain product recalls, reduce product waste and improve overall process efficiency.

White Paper Download:

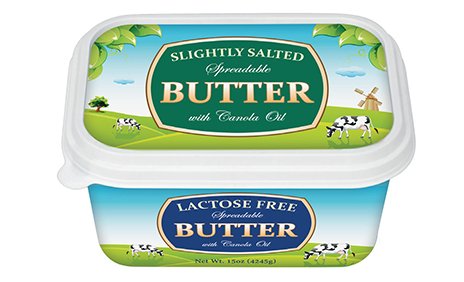

Minimize Rework

Production lines often see multiple varities of a product as they move through the day, and executing product changeovers is an action where it is easy to make a mistake. The sooner these mistakes are caught, the better: machine vision inspection systems can quickly identify an incorrect label and alert operators to the error. That means fewer erroneously labeled products to rework, which in turn means personnel can focus on other tasks.

Mitigate Recalls

While product recalls are sometimes unavoidable, it is in the best interest of any manufacturer to do whatever can be done in order to mitigate the risk of a product recall. Labelling errors represent a significant number of product recall reasons, and installation of a vision inspection solution can virtually eliminate the chances of a product with a labelling error making it into the distribution network. By identifying and removing non-complying packaging in the production facility, errors are corrected with far less money and manpower required.

White Paper Download:

Reduce Waste

Timing is everything when it comes to catching errors, and before putting valuable product into a package it helps to make certain the right package is being used. Vision inspection can verify the correct package is present before filling, keeping the potential for wasted product low. If labels are applied after filling, their contents can be verified before application to the packaging itself - again reducing the potential for wasted product.

Download this Vision Inspection Systems Infographic, detailing how to reduce costs:

Improve Efficiency

Monitoring product quality provides an important view of the production process. By keeping track of trends such as defect type, manufacturers can better plan maintenance of their production equipment. Vision inspection equipment can share valuable data with other production equipment on the line as well, even making adjustments to system settings on the fly in order to correct minor issues before they become a larger problem.

Download Comparison of Vision Inspection Systems Infographic:

Protect Brand Image

Product recalls and poor product presentation damage the image consumers and distribution partners have of your brand. By catching these simple labeling errors before they can make it to a warehouse or a retailer's shelf, vision inspection safeguards brands against damage to their image, helping to maintain a reputation of high quality products.

FAQs

How expensive are machine vision inspection systems?

This depends entirely on the complexity of the system. A single smart camera may be all that is required – although it is not as simple as mounting the vision inspection camera and turning it on. It needs to be connected to a rejection system (assuming you want to remove the defective products), which is not terribly complicated but does add a cost .The simplest of set-ups will not likely exceed $5000 in cost, while complex systems may reach the $60,000 range. Unsurprisingly, this has made the integration of vision inspection components into other production equipment attractive.

What is an integrated machine vision system?

Rather than a stand-alone vision inspection system, an integrated vision system is part of a larger piece of production equipment. For example, a filling system may have a vision element verifying the fill level, or a labeler may have a camera verifying label information before application.

Do I need a vision system?

The short answer is "maybe." The long answer is "it depends on how many things you need to inspect on a package and how fast," along with "how big of a risk do you want to take that something makes it to market with a labeling error?" It is the most effective way to verify the quality and content of every product label or package on a production line. How important the ability to do so is for your business is up to you.

Smart Cameras vs PC-based machine vision systems?

The largest and most obvious difference between the two is that a smart camera cannot receive data from multiple inputs. That is to say, a PC-based machine vision system can handle the operation and processing of multiple images from multiple cameras, whereas a smart camera is only capable of processing input from itself.

What can a vision inspection system manufacturer offer me?

Getting a system is not the same thing as buying a smart camera. It is of course possible to go it alone – buy a vision inspection camera and figure out how to make everything work on your own. What you miss out on is working with someone who knows everything that needs to go into the creation of an effective vision inspection program. You also get access to someone who can provide service on the system should something go wrong.

What are the advantages of machine vision?

Simply put, vision inspection allows for the rapid verification of product labeling and packaging as it moves down the production line. This allows you to achieve a stronger quality control program than manual inspection or random sampling, while also freeing up personnel for other more useful tasks.