We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

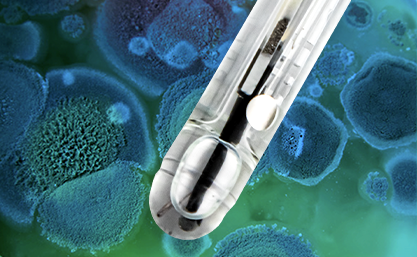

Bioreactor pH Probes

Achieve Optimal pH Control in Cell Culture & Fermentation

METTLER TOLEDO bioreactor pH probes are highly reliable measurement tools designed to enable ideal growth conditions to maximize yield and ensure batch-to-batch consistency under microbial and animal cell culture bioprocessing conditions. These pH probes for bioreactors are designed for bioprocessing and can withstand sterilization and sanitization processes. Intelligent Sensor Management (ISM) predictive diagnostics help reduce the risk of sensor failure during long cell culture batches.

Sensors for Various Bioreactor Capacities & Applications

METTLER TOLEDO pH sensors are ideal for scale-up. The same sensor model can be used in all bioreactor sizes, from benchtop R&D bioreactors to large scale bioreactors in commercial phase manufacturing.

Easy to Clean for Use Under Sterile Conditions

These sensors withstand sterilization and sanitization processes that are common in pharmaceutical sanitary environments, making them ideal for cell culture pH and fermenter pH monitoring and control.

Manufacturing Consistency for Media & Buffer Preparation

The accuracy and response time of METTLER TOLEDO pH probes is crucial to induce reliable batch uniformity upstream (media preparation) and downstream (buffer preparation).

Maintain Optimal Conditions to Maximize Yield

Bioreactor pH probes help maintain optimal pH control for fermentation and cell culture, resulting in faster growth rates and higher yields.

Maximize Process Safety During Separation and Purification

Performing accurate in-line pH measurement in bioreactors is crucial as it can affect downstream chromatography steps and purification performance.

Ideal for Developing Scale-Up & Scale-Down Studies

METTLER TOLEDO pH sensors for bioreactors also offer simultaneous ORP measurement. This helps build your oxygenation strategy while allowing you to use the same sensor in PD as in production.

Bioreactor pH Probes with ISM Predictive Diagnostics

Select METTLER TOLEDO pH probes for bioreactors offer ISM technology, which helps better monitor and manage sensor lifetime before sterilization and during a batch.

Explore our Services - Tailored to Fit your Equipment

Training & Consulting

FAQs

What are METTLER TOLEDO bioreactor pH probes?

Bioreactor pH probes are highly reliable measurement tools designed to support ideal growth conditions, batch-to-batch consistency and to help maintain quality attributes in diverse microbial or cell culture environmental process conditions. METTLER TOLEDO offers a full range of bioreactor pH probes with excellent repeatability for the most critical product applications. The pH probes for bioreactors are designed to withstand sterilization and harsh CIP conditions and are available with Intelligent Sensor Management (ISM) advanced diagnostics to prevent pH sensor failure during long batches.

What is the better choice for use with pH probes for bioreactors, liquid or gel electrolytes?

For bioprocessing, bioreactor pH probes with a pre-pressurized liquid electrolyte reference system are typically the best choice, because they show the highest reproducibility through several sterilization cycles.

What is the difference between the InPro 3100 and InPro 3250 model families?

The InPro 3100 is a pH sensor that uses a gel electrolyte, while the InPro 3250 and 3253 are pre-pressurized, liquid filled pH sensors. Designed with silver-ion traps, both the InPro 3100 and InPro 3250-53 are especially helpful for reducing long-term sensor maintenance by keeping the reference junction clear. In addition, the InPro 3250 offers a wide selection of different pH-sensitive glass membranes to consistently ensure the best measurement performance to meet your process demands. Both analog and ISM versions are available in a variety of lengths, optimal for different installation requirements. Available InPro 3100 sensor lengths include 120 mm, 150 mm, 225 mm, 325 mm and 425 mm. Available InPro 3250 sensor lengths include 120 mm, 225 mm, 325 mm and 425 mm.

What ISM technology features are available in these sensors?

Intelligent Sensor Management (ISM) technology offered with METTLER TOLEDO bioreactor pH probes provides a number of useful benefits that analog sensors cannot deliver. ISM advanced diagnostics help you manage the maintenance of your sensors throughout the run of your bioreactor. Plug and Measure installation is available, along with calibration and other information that is stored within the sensor. Self-diagnosing ISM electrodes used during fermentation or cell culture can specify if a sensor can be safely reused in the next batch. Finally, ISM provides simpler traceability and reporting for regulatory compliance.

How can ISM prevent pH sensor failure during cell culture or fermentation?

If a pH sensor fails during a fermentation process, dosing of chemicals must be interrupted, and saving the batch is only possible with lab pH measurement and manual adjustment at the bioreactor. Intelligent Sensor Management (ISM) technology offers powerful tools to minimize sensor failure. The digital signal output by ISM sensors is immune to interference, and corroded contact surfaces are also no longer an issue. ISM technology also offers pre-batch diagnostics to deliver precise information about sensor status. This can help predict when the sensor requires calibration or maintenance, or needs to be replaced. All of this data is available on the transmitter and on iSense sensor management software.