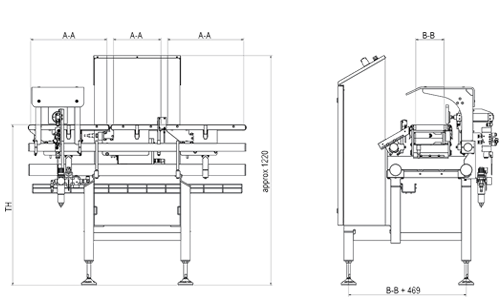

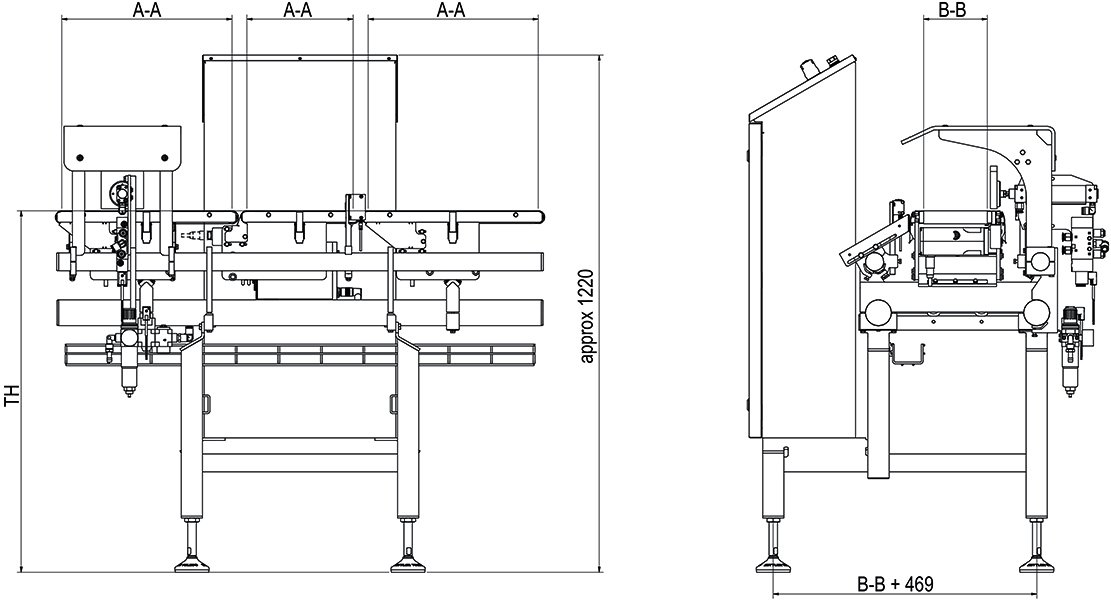

C33 PlusLine WD Checkweigher

Robust Performance.The C33 checkweigher combines reliable weighing accuracy with rugged machine design for harsh production environments. The system, including the HMI, is IP69 rated and proven resistant to most caustic detergents and high-pressure cleaning.

Resilient System Design

Suitable for the harshest of cleaning regimes, with an IP69 rating and proven resistance to most caustic detergents, disinfectants and high-pressure cleaning.

High Precision in Harsh Environments

High weighing precision with MID certification helps to comply with weighing regulations and reduces costly product waste.

Easy to Clean, Hygienic Design

Only four feet on the floor provide easy cleaning access while sloped surfaces prevent liquid retention and discourage bacterial contamination.

Material No.: 24003300200

| IP Rating | IP69 |

| Compatible Software | ProdX |

| Connectivity | Ethernet TCP/IP Fieldbus OPC UA |

| Inspection Solution | Checkweighing |

| Max Product Width | 400 mm |

| Max Weighing Zones | 5 |

| Weighing Technology | EMFR |

| HMI | 12" Touchscreen 7" Touchscreen |

| Packaging Type | Glass Metal Cans Plastic Trays Unpackaged |

| Product Flow | Conveyor |

| Inspection Application | Completeness Check Weight Control |

| Product Characteristic | Medium-Large Packages Open Round Container Small-Medium Packages Wet |

| Industry | Chemical Food & Beverage |

| Weighing Accuracy | from ±0.2 g |

| Industry Segment | Agriculture and Bulk Foods Beer, Wine and Other Alcoholic Beverages Dairy Meat & Poultry & Seafood Pet Food and Animal Feed Ready Meals Water and other Non-Alcoholic Beverages |

| Max Product Weight | 7 kg |

| Max Line Speed | 90 m/min |

| Max Throughput | 250 ppm |

Accurate, Reliable Weight Inspection

Designed for endurance and reliability with a throughput of up to 250 packs per minute and a weighing range of 25 g to 7 kg. Choose from over 150 configurable software, mechanical and product handling options for optimal performance

Fast Maintenance to Reduce Downtime

The conveyor belts can be released or removed entirely in 3 quick steps to support different hygiene and cleaning regimes, depending on customer requirements. The driving unit can also be dismounted and changed easily for maintenance purposes.

Prevent User Errors and Reduce Downtime

The C33 supports failsafe operation with error-safe reassembly of the conveyors. Rollers from the in-and outfeed conveyors cannot be accidentally added to the weighing conveyor. Self-adjusting, elastic belts remove the need for straining upon reassembly.

Support of Food Standards Compliance

The conveyor materials comply with Regulation (EC) 1935/2004, Regulation (EU) 10/2011, and FDA regulations governing the same for direct food contact.

Intuitive Operation with 12" Touchscreen

The color touchscreen is positioned at the front for increased worker safety and is resilient to harsh cleaning with a full IP69 rating, eliminating the need for a cover. The HMI provides access to key data and statistics in over 30 languages.

Data Collection Supports Conformity

Open interfaces such as OPC UA, PackML, and Fieldbus enable IoT/Industry 4.0 initiatives so that production data can be accessed, analyzed, and controlled anytime and anywhere. Optional integration with ProdX, METTLER TOLEDO's Data Management Software.

Global Service Support

A global network of service experts provide fast remote and on-site support. Our comprehensive service offering allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.