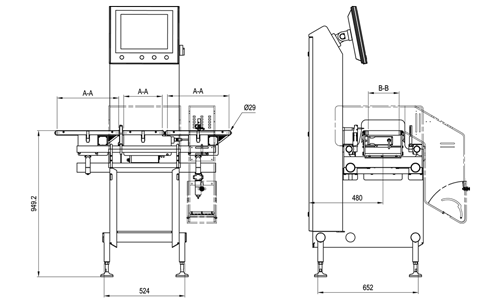

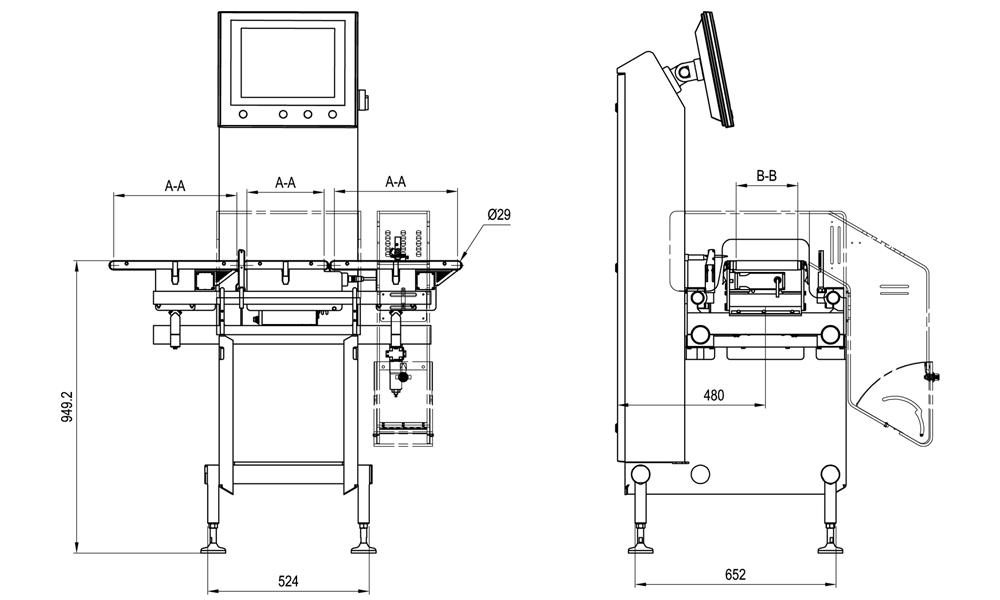

C35 AdvancedLine Pharma Checkweigher

Precision and Versatility.Precision checkweigher delivering maximum brand protection with dedicated options for pharmaceutical process safety and functionalities supporting FDA 21 CFR Part 11 compliance and GMP requirements.

Completeness Checks for Quality Control

Precision weighing reliably detects if a pack of medicine contains the correct amount of blisters and an instruction leaflet for brand protection.

High Accuracy at Fast Speeds

Support productivity with a standard deviation and accuracy of 10 mg, a throughput of up to 800 packs per minute, and a weighing range from 0 to 300 g.

Quality Assurance Support

Protect production integrity with lockable catch bins, covers, sensors, digital position indicators and software options such as pharma statistics.

Material No.: 24003500100

| IP Rating | IP54 IP65 |

| Compatible Software | ProdX |

| Connectivity | Ethernet TCP/IP Fieldbus OPC UA |

| Inspection Solution | Checkweighing |

| Max Product Width | 400 mm |

| Max Weighing Zones | 7 |

| Weighing Technology | EMFR |

| HMI | 15" Touchscreen |

| Packaging Type | Bundles Cartons Cases Vials |

| Product Flow | Conveyor |

| Inspection Application | Completeness Check Weight Control |

| Product Characteristic | Capsule Small Individual Wrapped Products Small-Medium Packages Tablet |

| Industry | Pharma & Biotech |

| Weighing Accuracy | from ±0.01 g |

| Industry Segment | Cosmetics Food Additives Nutraceuticals Pharma |

| Max Product Weight | 300 g |

| Max Line Speed | 180 m/min |

| Max Throughput | 800 ppm |

Software Options Supporting Compliance

Individual user profiles with password protection and software options such as Local Audit Trail and Login Server support regulatory FDA 21 CFR Part 11 compliance by recording all changes implemented and providing data integrity for audit purposes.

Product Handling Increases Productivity

Enable optimum efficiency with top and bottom belts or side grips and maximum line efficiency with precision conveyors for small, lightweight products. Open flaps and askew package detection protect downstream machinery and avoid unplanned downtime.

Future-proof, Intuitive System Design

The stable frame with optimal resonant frequency supports maximum precision, while the modular system architecture enables future adaptations. The 15" intuitive multilingual touchscreen displays key weight, production and configuration data.

Precision Weighing for Highest Accuracy

Digital monoblock electromagnetic force restoration (EMFR) load cells designed and produced in Switzerland achieve high precision for lightweight products, while intelligent filter algorithms eliminate environmental vibrations and calculate the mean weight.

Documentation to Support Validation

The dedicated Equipment Qualification (EQ) Pack supports complete validation of the checkweigher, including machine-specific documentation. Comprehensive equipment testing including IQ/OQ procedures support compliance with FDA and GMP regulations.

Simple Production Line Integration

Full integration capabilities available to tailor the checkweigher to your production needs, including networking for multiple checkweighers, communication interfaces and optional line monitoring systems.

Global Service Support

A global network of service experts provide fast remote and on-site support. Our comprehensive service offer allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.