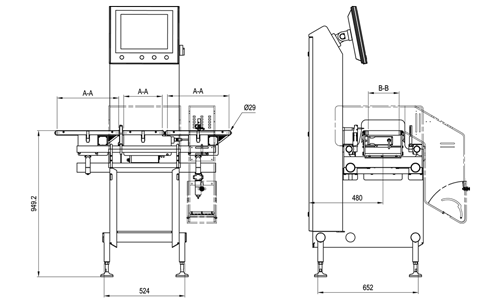

CM35 AdvancedLine WD Checkweigher

Built for operation in harsh environments, the CM35 WD combines metal detection and precision weighing in a single compact, space-saving device. Ideally suited as a critical control point (CCP), the stable, resilient system is fully IP69 rated.

Compact, Easy-to-clean Design

At only 4 feet in height when situated on the floor and with sloped surfaces, this combi system prevents liquid retention and bacterial contamination.

Food Standards Compliance Support

All materials with direct food contact fully comply with Regulation (EC) 1935/2004, (EU) 10/2011 and FDA regulations governing the same.

Reduced cleaning downtime

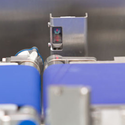

Quick, toolless, failsafe disassembly and assembly of the metal detector and weighing conveyors supports rapid cleaning processes.

Material No.: 24003510200

| IP Rating | IP69 |

| Compatible Software | ProdX |

| Connectivity | Ethernet TCP/IP Fieldbus OPC UA |

| Inspection Solution | Checkweighing-Metal Detection |

| Max Product Width | 400 mm |

| Max Weighing Zones | 7 |

| Weighing Technology | EMFR |

| HMI | 15" Touchscreen |

| Packaging Type | Glass Metal Cans Plastic Trays Unpackaged |

| Product Flow | Conveyor |

| Inspection Application | Completeness Check Weight Control |

| Product Characteristic | Medium-Large Packages Open Round Container Small-Medium Packages Wet |

| Industry | Chemical Food & Beverage |

| Weighing Accuracy | from ±0.2 g |

| Industry Segment | Agriculture and Bulk Foods Beer, Wine and Other Alcoholic Beverages Dairy Meat & Poultry & Seafood Pet Food and Animal Feed Ready Meals Water and other Non-Alcoholic Beverages |

| Max Product Weight | 7 kg |

| Max Line Speed | 90 m/min |

| Max Throughput | 250 ppm |

Maximum Sensitivity and Performance

The system comes with either a Profile Advantage, Profile R / RZ or Profile Combi LS metal detector. All are high performing and application specific, and detect the smallest metal contaminants to ensure maximum brand protection and product quality.

Rapid, Intuitive Product Changeover

During product teach-in, the metal detector automatically makes the necessary adjustments and automatically selects the best setup. Product changeovers are then easily carried out via the checkweigher HMI to speed up the process whilst reducing operator training needs.

Special conveyor design

The dedicated non-metal conveyor can be removed from the metal detector tunnel without the need for tools. The special conveyor design allows for quick, simple belt changes and reduces cleaning times.

High weighing precision

Maximum precision with MID certification helps to comply with weighing regulations and reduces costly product waste. Designed for ultimate precision at a maximum throughput of 250 packs per minute and a weighing range from 25 g to 7 kg.

Intuitive 15" Master Touchscreen

Product changes can be carried out efficiently via the large master HMI, which displays key weight, production and configuration data in over 30 languages. It is resistant to most caustic detergents and pressure cleaning without requiring a cover.

Global Service Support

A global network of service experts provide fast remote and on-site support. Our comprehensive service offer allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.