C35 AdvancedLine Checkweigher

High performance checkweighing.High performance checkweigher suitable for challenging weighing applications. Advanced FlashCell™ EMFR technology delivers maximum accuracy at throughputs up to 800ppm. The modular design offers customization to effectively handle any package type.

Performance Excellence

This system offers the flexibility to support all product sizes and weighing challenges with maximum precision at fast throughputs.

Product Handling Excellence

Achieve maximum process stability and equipment efficiency through transition, transport, stability and sorting options for any packaging format.

Software and Control Excellence

Exceptional process optimization with a wide range of standard and customizable, sophisticated software enhancements and control options.

Material No.: 2400350000

| IP Rating | IP54 IP65 |

| Compatible Software | ProdX |

| Connectivity | Ethernet TCP/IP Fieldbus OPC UA |

| Inspection Solution | Checkweighing |

| Max Product Width | 400 mm |

| Max Weighing Zones | 7 |

| Weighing Technology | EMFR |

| HMI | 15" Touchscreen |

| Packaging Type | Bags Bottle Bundles Cardboard Cartons Cases Composite Cans Flow Packs Metal Cans Trays VFFS |

| Product Flow | Conveyor |

| Inspection Application | Completeness Check Weight Control |

| Product Characteristic | Deep Frozen Dry Medium-Large Packages Open Round Container Small Individual Wrapped Products Small-Medium Packages Wet |

| Industry | Chemical Food & Beverage Metal, Plastic and Electronics Components |

| Weighing Accuracy | from ±0.1 g |

| Industry Segment | Automotive Bakery and Confectionary Beer, Wine and Other Alcoholic Beverages Cosmetics Dairy Fine and Specialist Chemicals Food Additives Meat & Poultry & Seafood Nutraceuticals Oils and Fats Pet Food and Animal Feed Ready Meals Snack Foods Sugar Starch and Yeast Water and other Non-Alcoholic Beverages |

| Max Product Weight | 10 kg |

| Max Line Speed | 180 m/min |

| Max Throughput | 800 ppm |

Data Governance to Support Performance

Over 10 different interface / protocol combinations including Ethernet, Fieldbus and OPC technologies enable IoT / Industry 4.0 initiatives so that production data can be accessed, analyzed and controlled anytime and anywhere.

Multiple Integration Options

Available as a space saving combination system with either metal detection, vision inspection for label check, x-ray inspection, or Track and Trace technology. Ideally suited as a Critical Control Point to safeguard brand reputation.

Optimized Production Efficiency

Complete line integration to reduce give away via filling machine feedback control. Combined with statistics, this function allows full control of fill levels to fulfil net content regulations whilst keeping costly product waste to a minimum.

Intuitive Operation

The 15" color touchscreen offers individual user access profiles with password protection. Easily view key weight, production and configuration data in over 30 languages and benefit from machine messages communicated in clear text for easy understanding.

Easy to Clean

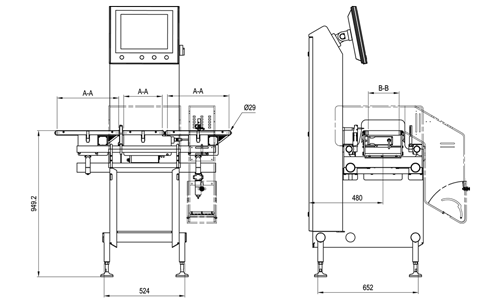

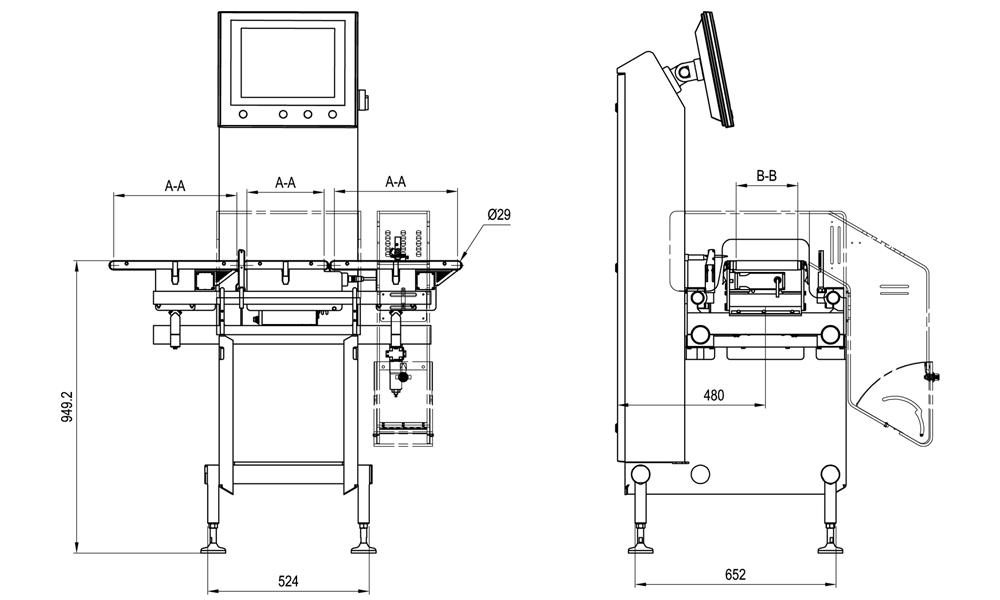

With only 4 feet on the floor, the system provides easy cleaning access whilst sloped surfaces prevent product retention. Easy conveyor belt changes and removable catch bins support fast cleaning across different environments.

Weighing Technology and Approval

The high performance EMFR load cell with FlashCell™ technology delivers exceptional accuracy at highest throughputs. Optional MID certification helps to comply with local weighing regulations and reduces costly product waste.

Global Service Support

A global network of service experts provides fast remote and on-site support. Our comprehensive service offering supports regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.