We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

In-line Dissolved Oxygen Sensor

High-performance, In-line DO Probes for Accurate Measurement

In-line dissolved oxygen sensors are analytical instruments designed for continuous DO monitoring with real-time results for a range of industrial processes. Industrial dissolved oxygen probes offer a rugged yet simplistic design to ensure accurate measurement in all process conditions. To ensure all requirements are met, METTLER TOLEDO offers in-line DO sensors for pharmaceutical, food and beverage, chemical and power industries, microelectronics and pure water applications.

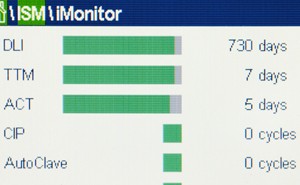

Increased Reliability Through ISM Technology

In-line DO sensors with Intelligent Sensor Management (ISM) technology use predictive diagnostics to monitor sensor maintenance needs for greater process availability and productivity.

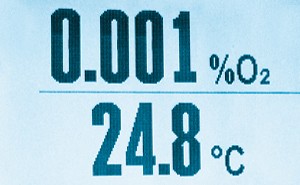

Accurate In-Line DO Probes with Low Detection Limits

METTLER TOLEDO offers in-line DO sensors that provide consistently reliable measurement accuracy, even at trace, ppb-level detection limits, making them suited for pure water and brewing.

Quick In-Line DO Sensor Start Up

Plug and Measure technology in ISM in-line DO sensors allow a sensor to be calibrated away from the process in a controlled environment. This enables fast, error-free measurement point start up.

In-Line DO Sensor Technology to Meet Your Requirements

METTLER TOLEDO in-line DO sensors are available in both optical and amperometric technologies. Various membrane materials help ensure you have the right in-line DO probe for your process.

Measurement for a Range of Industrial Processes

In-line DO sensors provide reliable DO measurement for processes in biotechnology, pharmaceutical development, brewing, chemical manufacturing and water purity monitoring.

Low Maintenance with Predictive Diagnostics

The simplistic design of in-line DO sensors makes maintenance straight-forward and effortless. Predictive diagnostics also notifies users of required maintenance before measurement is compromised.

Hygienic Design for Clean Environments

Select in-line dissolved oxygen probes are designed for hygienic applications. They are steam sterilizable and autoclavable to fulfill industrial requirements for hygienic design and traceability.

Explore our Services - Tailored to Fit your Equipment

Support & Repair

FAQs

What is dissolved oxygen (often called DO or O₂)?

Dissolved oxygen is the level of free, non-compound oxygen, which is present in water or another liquid. In industrial processes or pure water systems it is typically measured with an in-line dissolved oxygen sensor.

What is an in-line dissolved oxygen sensor?

In-line dissolved oxygen sensors are analytical instruments designed for continuous DO monitoring and control with real-time results for a range of industrial processes. In-line DO sensors from METTLER TOLEDO are optimal for in-line DO monitoring and control in pharmaceutical production, brewing, chemical production and pure water monitoring.

Why is dissolved oxygen measured with an in-line DO sensor?

Monitoring and managing oxygen levels are important in many industrial processes. In-line DO sensors help optimize product yield and quality, reduce costs and ensure product safety.

How does an in-line dissolved oxygen sensor work?

Dissolved oxygen analyzers work based on the technology of METTLER TOLEDO in-line DO sensor selected. METTLER TOLEDO offers two in-line DO sensor technologies: Amperometric and Optical.

Amperometric: These in-line dissolved oxygen sensors use a gas permeable membrane to separate the sample from the electrochemical cell inside. Oxygen diffuses through the membrane in direct proportion to the partial pressure of oxygen in the liquid outside the in-line DO sensor. A cathode and anode inside the probe are polarized with a voltage to enable the electrochemical reaction of oxygen. Oxygen is reduced at the cathode while the anode is oxidized, producing a small current in direct proportion to the amount of oxygen in the sample. In addition, the dissolved oxygen sensor uses the temperature value to convert the oxygen partial pressure signal to a dissolved oxygen concentration value by compensating for the changing solubility of oxygen with temperature.

Optical: These in-line dissolved oxygen probes use optical technology for measurement. They contain an oxygen-sensitive layer that can fluoresce. This layer absorbs light from a light emitting diode in the sensor, and the light is released as fluorescence. The fluorescence lifetime depends on the amount of oxygen present in the sample medium.

How do you calibrate an in-line dissolved oxygen analyzer?

Each in-line DO sensor has a specific calibration process than can be followed on its transmitter, or with ISM sensors, away from the process. To ensure high measurement accuracy of the in-line DO sensor, calibration must be carried out after each exchange of a sensor's spare part(s). Dissolved oxygen sensor calibration can be performed as a 1-point or 2-point calibration. For the 1-point calibration the normal calibration medium is air, for a 2-point calibration additionally a gas with 0% oxygen has to be used, which normally is pure nitrogen. The DO sensors can be adjusted also with a process calibration following a process sample or gas.

Are there in-line DO probes with Intelligent Sensor Management (ISM)?

METTLER TOLEDO produces a wide range of in-line DO sensors with ISM technology. These sensors offer a strong digital signal to prevent signal interference so you can place your dissolved oxygen analyzer wherever you need it. They offer predictive diagnostics so that you know when your in-line DO sensor needs replacement parts or calibrated. With Plug and Measure technology you can calibrate your in-line DO sensor away from the process for fast sensor swapping when sensor exchange is required.