The Technique

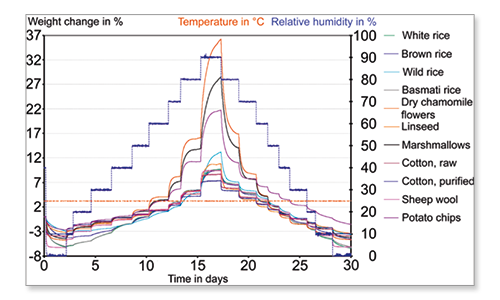

Dynamic Vapor Sorption, or DVS, is a gravimetric technique that measures the mass of a sample as it changes in response to programmed changes in temperature or humidity. A typical experiment exposes a sample to an environment where the temperature is held constant and the humidity is varied in a stepwise fashion.

The sample mass must be allowed to reach gravimetric equilibrium before proceeding to the next humidity step. The mass change at each step is recorded which allows the moisture sorption isotherm to be generated. These experiments are often very long as the sample equilibration times are slow. This makes traditional approaches expensive and time consuming. The ProUmid DVS systems solve this problem by studying up to 23 samples simultaneously.

In a DVS study, the sorption isotherm consists of two components: sorption and desorption. Sorption occurs during increasing humidity steps where the material takes up moisture while desorption occurs during decreasing humidity steps where moisture is lost. Sorption can be further investigated by separating absorption (moisture on the surface) from adsorption (moisture that penetrates into the bulk).

The difference between moisture sorption and desorption is called hysteresis and can prove useful when characterizing a material's interaction with moisture and its porosity. In addition, the ProUmid SPS DVS allows the use of in situ photography and Raman spectroscopy to characterize the physical changes associated with the gain or loss of moisture.

Applications

While the sorption isotherm determination is the most common application for DVS instruments, other applications include:

- Investigation of moisture induced changes to the glass transition

- Amorphous to crystalline conversions

- Gain and loss of hydrates

- Sample deliquescence

Films can be studied for permittivity per EN ISO 7783-1 part 1: 'Dish method for free films' and allows the accurate determination of the water vapor permeability of foils and films.

The ProUmid Software allows the weight changes in response to humidity and temperature to be monitored in real time. After the experiment is complete, detailed analysis of the data is simple to complete and can be exported to other programs for further analysis. The 21CFR Part 11 software package ensure that the ProUmid Test system is fully compliant and traceable.

Industries

Dynamic Vapor Sorption experiments prove to be useful in numerous industries. The food industry is interested in both the effect of moisture on food products as well as the permeability of packaging. Pharmaceutical companies are concerned with how humidity can change structure and polymorphic nature of materials, affect degradation and storage life, and affect handling.

Construction suppliers need to know how humidity affects building and insulation materials. The effects of humidity on materials are wide spread - any material that can be affected by humidity can be studied in the ProUmid DVS.