Explosion-Proof Floor Scales - Intrinsically Safe

Floor scales for safe and accurate weighing in Ex-zones

Explosion-proof floor scales and platforms for hazardous areas classified as Zone 1/21, Division 1 and Zone 2/22, Division 2 enable accurate weighing in areas where an explosive atmosphere may occur during operation. These intrinsically safe floor scales are designed to deliver long-term safety, productivity and quality for a wide range of weighing capacities.

High Precision Scales in Action

When you must fulfill tight tolerances, these platforms provide the accuracy you need. Watch the video to learn how the platform design enables the highest precision in production environments and how this can help you improve your weighing processes and ensure consistent quality, increase productivity and meet regulations. Watch the Video Read more

Watch the video of PFA584/589 Floor scales

At METTLER TOLEDO, we know the needs of every industry are different, which is why the PFA5 is not a one-size-fits-all solution. We have taken the pain out of the floor scale procurement process by creating an easy-to-order, globally standardized set of components that can easily be mixed-and-matched to formulate your ideal scale. Read more

Hazardous Area Safety Competence Guide

Safety is crucial for businesses that operate in potentially explosive environments. The free comprehensive guide provides you with extensive knowledge about explosion protection methods, standards and regulations and installation, operation and maintenance of weighing equipment in hazardous areas. Read more

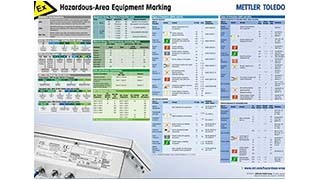

Hazardous Area Equipment Marking Poster

Easy and quick identification of markings and protection methods can help operators ensure weighing equipment complies with appropriate regulatory hazardous area standards. A Poster provides a structured overview on global electrical labeling standards, hazardous-area classifications and equipment ignition-protection types. Read more

Intrinsic Safety White Paper

Intrinsic Safety is the protection method of choice when it comes to ensuring process safety while improving production efficiency. The white paper explains the principles of the Intrinsic Safety protection method and discusses the advantages it has for weighing applications in hazardous areas. Read more

Explore our Services - Tailored to Fit your Equipment

We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

Support & Repair

Maintenance & Optimization

Calibration & Quality

Training & Consulting

Professional Installation - Get it right from the start

FAQs

What are explosion-proof floor scales? What are hazardous area floor scales? What makes an explosion-proof floor scale safe?

An explosion-proof floor scale, or hazardous-area floor scale, is approved for use in classified hazardous areas by regulatory authorities. Explosion-proof floor scales and hazardous-area floor scales provide safe, efficient and reliable weighing in potentially explosive environments.

A floor scale is considered safe for Ex-zones when the user has done an equipment risk assessment by identifying the type and duration of the explosion risk and then selected correctly designed equipment. Equipment, such as scales, needs to be approved and manufactured according to all relevant standards, which includes an approved maintenance plan for continued service.

Differences between explosion-proof floor scales Zone 1/21 Division 1 and Zone 2/22 Division 2?

Zones are classified by the by the International Electrochemical Commission (IEC) in Europe, Asia, Australia, Africa and other regions or the National Fire Protection Association (NFPA) National Electric Code (NEC) in the United States

Class I Division 1 hazardous areas are locations that are defined within the NEC Handbook, articles 500, 501, 502, 503, 505, and 506. Class I locations are those in which flammable gases or vapors are present in the air in quantities sufficient to produce explosive or ignitable mixtures (NEC 501). Division 1 is a subset of Class I and is classified as an area where the explosive or flammable gases, vapors or liquids mentioned above can exist under normal, everyday operating conditions.

One characteristic of Zone 2 areas is when ignitable concentrations of flammable gases or vapors are not normally present but could be present in certain cases that are clarified in the NEC standards. Zones are also classified by ATEX 1999/92/EC Directive based on the frequency and duration of the occurrence of the explosive atmosphere. Zone 2, according to ATEX 1992/92/EC Directive, is when an explosive atmosphere is likely to occur infrequently or for short periods of time.

Explosion-proof floor scales are approved for Zone 1/21 Division 1 and Zone 2/22 Division 2 based on their ability to achieve the level of safety required in the above defined environments.

For more information on selecting explosion-proof floor scales or explosion-proof area classification, download the Hazardous Area Competence Guide.

How to know if an explosion-proof floor scale will work in your environment?

In order to determine if a specific hazardous-area floor scale will work for your environment, you must first determine the hazardous location classification, as defined by the International Electrochemical Commission (IEC) in Europe or the National Fire Protection Association (NFPA) National Electric Code (NEC) in the United States. Then, you must select a scale that has the appropriate approvals for your explosion-proof area classificaton.

Why MT explosion-proof floor scales are intrinsically safe? How do you know if a device is intrinsically safe?

Intrinsically safe systems enable equipment to be used without risk of igniting any flammable gas, dust or fibers that may pre-sent in hazardous areas. Through rigorous testing, METTLER TOLEDO has to prove the intrinsically safe floor scales can withstand the requirements of the specified regulatory bodies’ approvals by supplying certificates of conformity, drawings and other supporting materials.

Intrinsic safety offers three classification levels, "ia," "ib" or "ic," which are based on the safety level and number of faults possible. Each classification attempts to balance the probability of an explosive atmosphere being present against the probability of an ignition occurring. The level of protection "ia" is a prerequisite for Category 1 equipment and is suitable for use in Zone 0/Division 1. The level of protection “ib” for Category 2 equipment is suitable for use in Zone 1. The level of protection "ic" for Category 3 is suitable for use in Zone 2/Division 2.

For intrinsically safe floor scales installed in a fixed location, the maximum interval between periodic inspections should not exceed three years without seeking expert advice. Once an interval is determined, additional periodic inspections should be performed to support or modify the proposed interval. Moveable or portable intrinsically safe equipment is more prone to damage or misuse than fixed installations and therefore the interval between periodic close inspections should be a maximum of every 12 months. Enclosures that are frequently opened, such as battery housings, should have a detailed inspection at least every six months. Additionally, all equipment should be visually inspected by a trained operator before use to ensure that it is not obviously damaged.

For more information, download the Hazardous Area Competence Guide.