Glass Transition Determination Instruments

Investigate Tg with the Help of Thermal Analysis

The glass transition (Tg) is the temperature range at which a material changes from a hard, brittle state to a soft, rubbery state. Thermal analysis is a powerful set of techniques, that are commonly used to study the glass transition of materials. Knowledge of the glass transition temperature and behavior of materials helps to optimize the processing conditions and final properties of materials for different applications.

Advantages

Modular Design

Modularity is at the core of METTLER TOLEDO thermal analyzers, enabling us to offer tailor-made solutions for almost all academic and industrial applications. Should requirements change after installation, the instrument can be upgraded as needed.

Reliable Automation

Our TGA and DSC systems support fully automated workflows – from sample loading to result analysis and report generation. Up to 34 samples can be processed by our robust, factory endurance-tested sample robot.

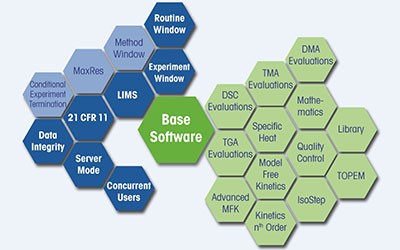

One Software for All Thermal Analysis Instruments

STARe is the most complete and comprehensive thermal analysis software, providing unrivalled flexibility, unlimited evaluation possibilities, and the technical controls to support compliance.

Innovative Sensor Technology

Put your trust in METTLER TOLEDO’s world-leading sensor technology: whether you purchase a DSC, TGA, TMA, or DMA instrument, we guarantee exceptional sensitivity and highly accurate measurement results.

Simple Operation

STARe functionality is readily accessible from the software's intuitive ribbon interface. Standard features such as OneClick™ and multiple curve handling, as well as options like Quality Control and Reference Library, simplify daily lab work.

High-Level Competence & Support

Our global network of application specialists gives you access to the latest application know-how. Dedicated application specialists help to ensure that you obtain the most accurate thermal analysis results.

Explore Our Services - Tailored to Fit Your Equipment

According to the International Confederation for Thermal Analysis and Calorimetry (ICTAC), thermal analysis is group of techniques in which a physical property of a substance is measured as a function of temperature while the substance is subjected to a controlled temperature program.

Support & Repair

Training & Consulting

FAQs

How is glass transition determined by differential scanning calorimetry?

Glass transition is a function of a material's heat capacity. At the glass transition temperature, the Cp changes, which leads to a change in the slope of the measured heat flow. This change of slope can be used to determine the glass transition temperature.

Is thermogravimetric analysis (TGA) used for glass transition measurements?

Even though no mass change occurs during a glass transition, the TGA/DSC can determine the glass transition temperature of materials with the thermocouples that are in the sensors.

How is thermomechanical analysis (TMA) used for the determination of glass transition?

During a glass transition, there is an obvious dimensional change of a material due to a change in molecular mobility. TMA is very sensitive to this change and is therefore a very powerful tool for determining glass transition.

What type of information does dynamic mechanical analysis (DMA) provide about the glass transition of materials?

DMA measures the mechanical properties of a material as it is subjected to a sinusoidal stress or strain at a constant frequency, while being heated or cooled at a controlled rate. The molecular mobility change at a glass transition changes the modulus of a material, which allows the DMA to easily determine Tg. The glass transition is a frequency dependent property, which can be explored with DMA.