Low Retention Pipette Tips

For Viscous and Low Surface Tension Liquids

A low retention pipette tip works well with viscous and low-surface-tension liquids. Viscous (e.g., glycerol) and low-surface-tension liquids (e.g., isopropyl alcohol) adhere to the inside of standard pipette tips, increasing experimental uncertainty. The unique Rainin molding process creates tips with a highly repellent coating – a “superhydrophobic” surface over the entire tip. This prevents any adhesion between samples and the polypropylene tip surface, facilitating enhanced fluid movement.

Advantages of Low Retention Pipette Tips

Advanced Repellent Surface

The super-repellent surface of Rainin LR tips "normalizes" the flow characteristics of fluids with diverse compositions and physical characteristics (viscosities, surface tension, density, hydrophobicity, etc.). The result: enhanced pipetting accuracy across a broader range of sample types. Rainin LR tips provide greater peace of mind and better data fidelity when pipetting.

Ideal for Difficult Liquids

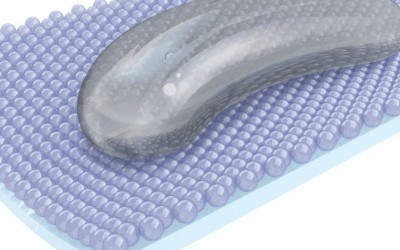

We employ a unique molding process to produce tips with a uniform field of highly-repellent fluoropolymer molecules that form an impenetrable “superhydrophobic” surface. The result: liquids and molecules are suspended above the polypropylene tip surface, allowing difficult liquids to glide effortlessly in and out of the tip.

Less Residual Volume

The uniform repellent fluoropolymer "field" on the surface of Rainin LR tips prevents any interaction between the sample and the polypropylene tip surface. In this short video, a propylene glycol-based food colorant demonstrates how Rainin LR low retention tips eliminate sheeting activity. By dramatically reducing the retained sample after dispensing, Rainin LR Tips eliminate a major source of pipetting inaccuracy.

FinePoint Tips for Pipetting Accuracy

FinePoint tips taper to a fine orifice diameter. Their slender design, in combination with thin, flexible walls, creates an exceptionally supple tip that assists in sample touch-off. The narrow orifice aperture and thin wall surrounding the orifice provides minimal surface area for residual sample to adhere to during sample dispensing.

Not All Low Retention Tips are Created Equal

More common manufacturing methods, such as dipping or tumbling tips in a fluoropolymer bath, can produce tips with incomplete and uneven coatings that can adversely affect pipetting accuracy. In addition, tips made with "diamond polished" molds – often touted as low retention – do nothing to prevent samples from reacting with the polypropylene and binding to the tip surface.

Documents

Expert Service – Tailored to Fit Your Pipetting Needs

METTLER TOLEDO supports and services your pipettes through their entire life-cycle, from good pipetting techniques to preventive maintenance and calibration to equipment repair.

Order Pipette Service & Calibration

Support & Repair