Temperature Modulate DSC Instruments

TMDSC Helps Separate Overlaying Thermal Effects

Temperature Modulated Differential Scanning Calorimetry (TMDSC) works by subjecting a sample to a temperature oscillation, which can be superimposed on a linear heating or cooling program. It is used to separate overlapping temperature-dependent and time-dependent thermal effects.

Advantages

Modular Design

Modularity is at the core of METTLER TOLEDO thermal analyzers enabling us to offer tailor-made solutions for almost all academic and industrial applications. Should requirements change after installation, the instrument can be upgraded as needed.

Reliable Automation

Our TGA and DSC systems support fully automated workflows – from sample loading to result analysis and report generation. Up to 34 samples can be processed by our robust, factory endurance-tested sample robot.

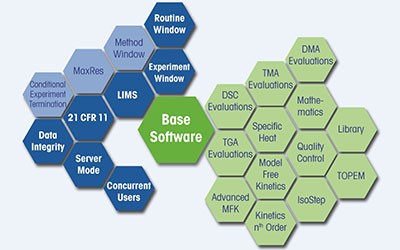

One Software for All Thermal Analysis Instruments

STARe is the most complete and comprehensive thermal analysis software, providing unrivalled flexibility, unlimited evaluation possibilities and the technical controls to support compliance.

Innovative Sensor Technology

Put your trust in METTLER TOLEDO’s world-leading sensor technology: Whether you purchase a DSC, TGA, TMA or DMA instrument, we guarantee exceptional sensitivity and highly accurate measurement results.

Simple Operation

STARe functionality is readily accessible from the software's intuitive ribbon interface. Standard features such as OneClick™ and multiple curve handling, as well as options like Quality Control and Reference Library, simplify daily lab work.

High-Level Competence & Support

Our global network of application specialists gives you access to the latest application know-how. Dedicated application specialists help to ensure that you obtain the most accurate thermal analysis results.

Explore Our Services - Tailored to Fit Your Equipment

According to the International Confederation for Thermal Analysis and Calorimetry (ICTAC), thermal analysis is group of techniques in which a physical property of a substance is measured as a function of temperature while the substance is subjected to a controlled temperature program.

Support & Repair

Training & Consulting

FAQs

What does latent heat flow stand for?

The term "latent heat flow" refers to the transfer of heat that accompanies a phase change in a substance. This heat is referred to as "latent" because it is not associated with a change in temperature, but rather with a change in the physical state of the substance (e.g. from solid to liquid or from liquid to gas).

What is sensible heat flow?

Sensible heat flow refers to the transfer of heat that is associated with a change in temperature of a substance, but not a change in its physical state.

What is the difference between latent and sensible heat flow?

The main difference between latent and sensible heat flow is the nature of the heat transfer. Sensible heat flow involves the transfer of heat between two substances that are at different temperatures, resulting in a change in temperature of the receiving substance. On the other hand, latent heat flow involves the transfer of heat between two substances that are at the same temperature, resulting in a change in the physical state of the receiving substance.

How does temperature modulated DSC separate the latent and sensible heat flows?

As a result of the modulation, the phase transition signal is split into two parts: a modulated component and a baseline component. The modulated component corresponds to the latent heat flow, which is associated with the phase transition itself, while the baseline component corresponds to the sensible heat flow, which is associated with the temperature change of the sample.

What techniques of TMDSC does METTLER TOLEDO offer?

METTLER TOLEDO offers three different measurement techniques for TMDSC, including ADSC, IsoStep, and TOPEM.

What is the advantage of temperature modulated DSC (TMDSC)?

With conventional DSC, it is not possible to separate the latent and sensible heat flows. In contrast, temperature modulated DSC, or TMDSC, enables the separation of the measured DSC output signal into what is called the reversing heat flow (cp information) and the non-reversing heat flow (excess heat production); this allows you to understand and interpret the different thermal events that occur in the sample and to distinguish between overlapping effects.