Vision Inspection System, V57

Customizable, precise quality control.Immediate contamination detection and precision formation inspections of rigid plastic containers.

Advanced Product Handling

Product tracking, product handling options, and intuitive software enable efficient visual inspection of every product.

Real Time Quality Control

Installed directly after product formation, the system minimizes chances that misformed or contaminated products continue to downstream processes.

Precise Package Presentation

Detect product contamination as small as 0.1 TAPPI for top-quality products.

Material No.: 2828420900

| Reading Devices | PC-Based Camera |

| IP Rating | IP54 IP65 |

| Compatible Software | ProdX |

| Connectivity | OPC UA |

| Inspection Solution | Visual Inspection |

| Max Product Width | 110 mm |

| HMI | 15" Touchscreen |

| Packaging Type | Bottle Plastic Vials |

| Product Flow | Conveyor |

| Max Camera Field of View | 300 x 200 mm |

| Label Quality Inspection | Graphical ID Label Placement Label Skew Label Wrinkles |

| Inspection Application | Cap Inspection Code Inspection Completeness Check Custom Inspection Fill level Check Integrity Check Label Inspection Seal Inspection |

| Product Characteristic | Medium-Large Packages Round Container Small-Medium Packages |

| Industry | Chemical Food & Beverage Metal, Plastic and Electronics Components Pharma & Biotech Transport and Logistics |

| Max Product Height | 200 mm |

| Industry Segment | Agriculture and Bulk Foods Automotive Bakery and Confectionary Bulk Chemicals Cosmetics Dairy Fine and Specialist Chemicals Food Additives Meat & Poultry & Seafood Nutraceuticals Oils and Fats Pet Food and Animal Feed Pharma Ready Meals Shipping and Mailing Snack Foods Sugar Starch and Yeast Water and other Non-Alcoholic Beverages |

| Number of Reading Devices | 14 |

| Max Line Speed | 100 m/min |

| Max Throughput | 600 ppm |

| Camera Inspection Area | Bottom Side Top |

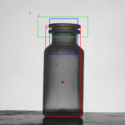

Sidewall Inspection

Check for contaminants, debris, cracks, or improper formation on sidewalls to verify only top-quality containers in advance on the production line.

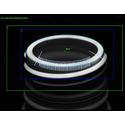

Verify Ovality Formation

Inspect proper plastic formation ovality or symmetry for packaging integrity in downstream packaging operations.

Customized Applications

Perform other custom inspection requirements, such as neck threading, container formation, or other package integrity inspections.

Easy-to-use Software

Intuitive HMI and standard configuration of inspection tools simplifies new product setup for efficiency.

Multiple Lighting Options

Our advanced lighting systems are designed to create optimal contrast to detect all defects on labeling and packaging.

Advanced Camera Configurations

Powerful pc-controlled cameras come in a variety of resolutions, lenses, and filters and are designed for optimum speed and performance for your application.

Global Service and Support

A global network of service experts provide fast remote and on-site support. Our comprehensive service offering allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.