Volume, Density and Magnetism Systems

Reliable Solutions for Accurate Measurements

Our systems for measuring volume, density and magnetism are highly precise instruments that provide essential information for the determination of mass above sea level for higher accuracy weight classes. Our volume, density and magnetism systems offer simple handling and guided processes to ensure measurements are highly accurate and compliant.

Advantages of Volume, Density and Magnetism Systems

Accurate Volume and Magnetism Determination

Our volume, density and magnetism measurement systems are based on state-of-the-art weighing technologies to ensure highly accurate mass determination that complies with regulations.

Unrivalled Performance Determining Volume and Density

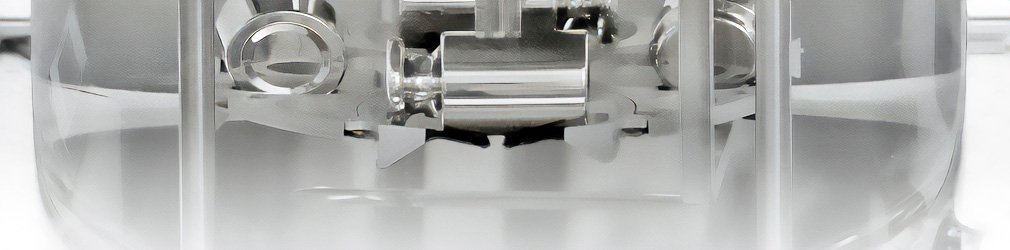

The VC1005X is a fully automatic system for fast and extremely accurate volume and density determination of weights from 1 g up to 1 kg.

Dual Use for Determining Mass and Volume

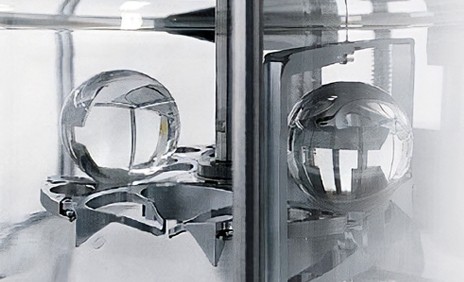

Our VMS systems make use of the built-in comparator balance for both determining mass and measuring buoyancy force for density determination. The weight handler and easy-access weighing pan ensure smooth operation.

Determine Magnetism with Highest Resolution

The S-50K susceptometer determines susceptibility with resolutions up to 1.2 x 10-6 and magnetization up to 0.00094 µT. This exceptional performance enables magnetism and susceptibility to be determined for weights from 1 g up to 50 kg in the highest weight classes: OIML E1 and ASTM E617-97 Class 0.

Traceability to Calibrated Standards

Our systems for volume, density, and magnetism ensure full traceability to national standards. All measurements are stored securely and comprehensive results reports can be generated at any time.

Intuitive User Guidance

Our sophisticated volume, density and magnetism software guides you through the individual measurement processes. It also captures data automatically, performs complex calculations, and provides you with a comprehensive report at the end.

FAQs

Why should I measure the volume and density of my weights?

The density of a weight has an influence on its weight measurement as the weight experiences a certain buoyancy in air. Together with the volume, the air buoyancy correction can be calculated and compensated for accordingly.

What is a susceptometer used for?

A susceptometer is used to determine the magnetic properties of a weight. These properties have an influence on the calibration of the weight and the underlying uncertainty.

When is it necessary to determine the volume and density of weights?

OIML states that for weights in high accuracy weight classes, the exact volume and density must be determined when the weights are used above certain altitudes. For E1 and E2 weights, the volume and density must be determined when more than 300m above sea level, and for F1 weights when more than 800m above sea level.

Is it a problem to have air bubbles on my test weights?

Yes, air bubbles on test weights can significantly bias your volume and density measurements. The test weights must be allowed to settle once they have been submerged and any air bubbles present should be meticulously removed in order to ensure accurate volume and density measurements. METTLER TOLEDO VMS systems include an advanced water jet system that efficiently and effectively removes air bubbles.

What is the difference between the VC system and the VMS systems?

The VMS systems are manual systems for determining volume and density. This means the built-in manual mass comparator can also be used for manual mass determination. The VC1005X is a fully automatic system dedicated just to the determination of volume and density. The automated process accurately determines the volume and density of up to 4 different weights without requiring input from the operator.

Do the VMS and VC systems come with special software?

Yes, all METTLER TOLEDO volume and density measurement systems are supplied with our proprietary software as a standard. This dedicated software simplifies the density determination process and enables you to generate highly detailed volume and density measurement reports.

Which OIML R111 methods are covered by VMS2, VMS20 and VC1005X for the calibration of density and volume of weights?

The International Organization of Legal Metrology (OIML) provides internationally accepted recommendations for the metrological characteristics of measurement instruments. The OIML also defines test methods for weights. The VMS2 and VMS20 volume measurement devices calibrate volume and density according to Method A1 (OIML R111-1, two different reference weights weighed in air) and Method A3 (OIML R111-1, direct weighing). The VC1005X volume mass comparator calibrates volume and density according to Method A2 (OIML R111-1 reference weights weighed in air and in liquid).