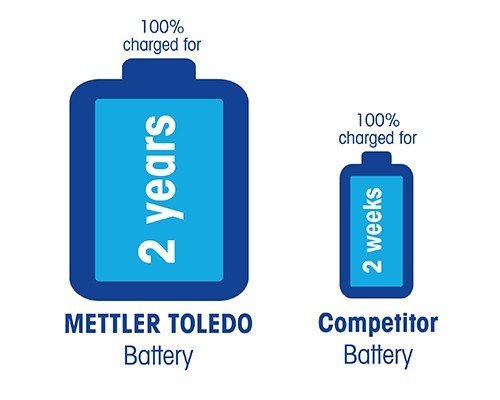

There are many benefits of going wireless with your floor scale solution. First of all, this provides the ultimate flexibility in placement of the scale itself. Traditional floor scale projects can be limited by cabling requirements, requiring strategic planning as to where the floor scale can be placed relative to power sources etc.

Additionally, traditional floor scales can require expensive and time consuming construction work if being done new or a move is required. For many facilities, floor scale cables must be 'buried' so that the cables are not exposed on the floor. This is to eliminate tripping hazards and ensure efficiency in the production area. But the consequence is expensive, dirty and time consuming construction. Concrete must be broken up, cords set, and then new concrete set. You can see how a wireless floor scale would save time and money in this regard.

Another benefit of wireless floors scales relates to Lean manufacturing and having what is necessary to produce on the floor. For many manufacturing facilities, they require a floor scale solution for processes some of the time, and in other processes, they are not using it. This is especially relevant in scenarios that include a 'clean room' – where certain applications will require the use of the floor scale, but then they might not use it for several days after, and space is very limited. A wireless floor scale offers the opportunity to use the scale when it is needed and easily remove it when it is not in use.

To discover more benefits of wireless floor scales, view the ACW520 brochure.