Floor Scales

Solutions to Increase Productivity and Ensure Accuracy

Floor scales are robust platforms available in many different sizes and designed for weighing loads from 600 kg to more than 25,000 kg in a variety of industries and applications from pharmaceutical manufacturing to logistics operations. These platforms may be individually configured to meet your precision, quality and environmental needs with options that include hygienic design for easy cleaning, hazardous area approvals for safety, and a broad range of accessories.

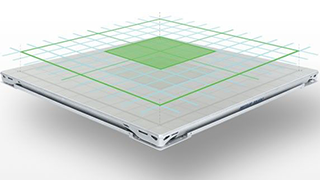

High Precision Scales in Action

When you must fulfill tight tolerances, these platforms provide the accuracy you need. Watch the video to learn how the platform design enables the highest precision in production environments and how this can help you improve your weighing processes and ensure consistent quality, increase productivity and meet regulations. Watch the Video Read more

Real-Time Operator Guidance

In tough industry applications, not only do you have the challenge to improve efficiency but also need to avoid defective products. In daily weighing activities, standard analog floor scales do not have the capability to warn you of possible errors. METTLER TOLEDO’s new generation floor scale Powerdeck™ delivers Real-Time Operator Guidance to help you operate efficiently and without errors. Read more

Watch the video of PFA584/589 Floor scales

At METTLER TOLEDO, we know the needs of every industry are different, which is why the PFA5 is not a one-size-fits-all solution. We have taken the pain out of the floor scale procurement process by creating an easy-to-order, globally standardized set of components that can easily be mixed-and-matched to formulate your ideal scale. Read more

Functional Design

Installing floor scales in pits is beneficial to allow easy loading and unloading of material on the ground level. The pit frames, which are available as an accessory for all floor scales, ensure short installation time and easy positioning and leveling. Read more

See how Powerdeck™ Increases Production Yields

This series of short videos gives quick insights into how Powerdeck™ can improve effiiciency and avoid defective products. Your production yield will increase through faster processing, increased precision, and elimination of measurment errors. Read more

PHD779 Low-Profile Floor Scales

Combine the power of POWERCELL® technology with our fully optimized hygienic design. The ultra-low-profile PHD779 platforms alleviate the most common floor scale challenges to speed up every part of your process, from loading and unloading to cleaning between cycles. Choose from the static, mobile, or easy-lift models to optimize your operation. Read more

Explore the 360° View of PHD779

Delve into the details of our innovative PHD scale designs. The 360° animation offers self-guided navigation of the three scale models: PHD779lift with a unique hygienic frame and fully sealed bottom plate; PHD779mobile with lock-and-go ramps and self-centering platform; and the PHD779static with large, low-profile platform sizes. Read more

Explore our Services - Tailored to Fit your Equipment

We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

Support & Repair

Maintenance & Optimization

Training & Consulting

- Digital Floor Scales

- Drum Scales

- Floor Scales for Dry Environments

- High-Precision Floor Scales

- Industrial Basics Scales

- Low-Profile Floor Scales

- Mild Steel Floor Scales for Manufacturing

- Pallet Jack Scales / Pallet Scales

- Portable Floor Scales

- Printers and Peripherals

- Stainless-Steel Floor Scales for Wet Areas

FAQs - Floor Scales

What are the benefits of using a floor scale?

Floor scales offer many benefits including:

- Accurate inventory management: With a floor scale, you can accurately weigh and track inventory, which can help you manage your stock levels and prevent overstocking or understocking.

Compliance with regulations: Depending on your industry, you may be required to use a certified floor scale to ensure compliance with regulations. A floor scale can help you avoid fines or penalties for non-compliance.

Floor scales support a large amount of weighing traffic under aggressive working conditions.

Ease of use: Floor scales are generally user-friendly and require little training to operate. They can be quickly and easily integrated into your workflow.

Versatility: Floor scales come in a variety of shapes, heights, accuracy levels, sizes, and weight capacities, making them suitable for a range of applications, from weighing packages to measuring large industrial equipment.

Space-saving: Floor scales can be designed to be compact and low-profile, taking up minimal space in your facility while still providing accurate weight measurements.

What are the main features of an industrial floor scale?

There are several main features to consider when looking for an industrial floor scale. Some of these features include:

Weight capacity: Industrial floor scales are designed to handle heavy loads, with weight capacities ranging from a few hundred pounds up to several tons.

Durability: Industrial floor scales are built to withstand harsh environments and heavy use. They are typically made from sturdy materials like stainless steel or mild steel and are designed to resist harsh cleaning procedures, corrosion, and damage.

Accuracy: Industrial floor scales need to provide accurate weight measurements, often with tolerances of ±0.1% or better. The type of load cell used dictates the level of accuracy you can achieve.

Connectivity: Many industrial floor scales are equipped with digital displays or can be connected to a computer or other device to log weight data and integrate with other systems.

Safety features: Industrial floor scales may include safety features like overload protection or non-slip surfaces to prevent accidents and protect workers.

Customization: Depending on your needs, you may be able to customize your industrial floor scale with features like ramps, guardrails, or other accessories to improve usability and safety.

Can floor scales be used in harsh or hazardous environments?

Yes, METTLER TOLEDO offers a variety of heavy-duty, intrinsically safe floor scales approved for hazardous zones including Zone 1/21, Zone 2/22, Division 1, and Division 2. You can browse the selection of floor scales that are available for your hazardous environment by filtering for your hazardous area rating on the floor scales product page, and then request a quote.

What is the capacity range of floor scales offered by METTLER TOLEDO?

METTLER TOLEDO offers floor scales that can weigh from 300 to 20,000 kg (500 to 40,000 lb) in readabilities from 5 g to 2 kg. Please let us know what you intend to weigh, and we will help you determine the scale that meets the needs of your application.

How do you install an industrial floor scale?

Installing an industrial floor scale requires some technical knowledge and expertise. Here are the general steps involved in installing an industrial floor scale:

Choose the location: Determine the ideal location for the floor scale, based on factors like the size of the items to be weighed, the traffic flow in the area, and the availability of power and data connections.

Prepare the foundation: The floor must be level and stable, with a solid, smooth surface to support the scale. The foundation should be free of cracks, bumps, or other irregularities that could affect the accuracy of the measurements. In some cases, you may dig a pit for floor scale installation that is completely flush with the floor.

Position the platform: Lift the floor platform to the proposed installation place and put it down slowly. Verify that every corner firmly touches the ground. If this is not the case, lift the floor platform and insert shims to level or adjust foot height if the level bubble is not in the center or any foot does not touch the ground fully.

Calibrate the scale: Depending on the scale type, it must be either adjusted or calibrated to ensure accurate readings. This may involve adjusting the load cells or making other fine-tuning adjustments.

Test the scale: Finally, the scale should be tested to ensure that it is operating properly and providing accurate readings. This may involve weighing various items of known weight to verify the accuracy of the measurements.

It's important to note that installation procedures may vary depending on the specific type and model of industrial floor scale you are working with, so it's always best to follow the Installation Manual and recommendations. Additionally, installation of an industrial floor scale is best completed by trained professionals with experience in the field.

How accurate are floor scales?

METTLER TOLEDO’s floor scale portfolio offers precision levels up to 30,000e legal-for-trade or up to 750,000d process resolution. The degree of accuracy depends on several factors, including the specific type of scale, its capacity, and its calibration. Most modern digital floor scales can provide measurements with a precision of at least 0.1% of the maximum weight capacity of the scale. For example, a 10,000-pound floor scale should be able to provide readings with a resolution of 10 pounds or less.

However, accuracy can be affected by factors such as temperature, humidity, and vibration. Changes in these conditions can cause the scale's components to expand or contract, which can result in measurement errors.

To ensure accuracy, floor scales should be calibrated regularly. The frequency of calibration depends on factors such as the scale's usage patterns, the environment in which it is used, and the accuracy requirements of the application. Regular calibration can help to minimize errors and ensure that the scale provides accurate readings over time.

In summary, floor scales can be very accurate, but the level of accuracy will depend on various factors and should be carefully monitored and maintained through regular calibration.

Does METTLER TOLEDO have dust and rust-resistant floor scales?

Yes, you can find METTLER TOLEDO floor scales suitable for dusty or harsh environments by filtering for IP65 protection or higher within the Environment filter options. Many of our stainless-steel floor scale models are built to withstand challenging environments, harsh cleaning agents, or regular washdown. Different stainless-steel options and surface finishes like grinded or e-polished can be selected when working with chemicals or harsh detergents.

Can industrial floor scales undergo intensive hygienic cleaning?

Yes, METTLER TOLEDO has a wide range of scales designed for use in hygienic applications. Many of our stainless-steel scales exceed normal requirements for even the most intensive hygienic cleaning processes.

What materials are used to make industrial floor scales durable and robust?

Industrial floor scales are designed to withstand harsh environments and heavy use, so they are typically made from durable and robust materials such as:

Steel: Steel is a popular choice for industrial floor scales because of its strength and durability. It is resistant to bending, warping, and corrosion, making it ideal for use in tough industrial environments.

Stainless steel: Stainless steel is another popular material for industrial floor scales. It is resistant to corrosion, staining, and rust, making it ideal for use in wet or damp environments where rust or corrosion could be a concern.

Aluminum: Aluminum is a lightweight material that is often used to make portable floor scales. It is also resistant to corrosion and is often used in food or pharmaceutical industries where cleanliness and hygiene are a top priority.

Concrete: In some cases, industrial floor scales may be embedded in concrete for additional stability and durability.

Overall, the materials used to make industrial floor scales are chosen for their strength, durability, and resistance to corrosion and other forms of damage. By using high-quality materials, industrial floor scales can withstand heavy use and harsh environments while providing accurate and reliable weight measurements.

What are floor scales and how are they used in industrial weighing applications?

Floor scales are large, flat platforms that are designed to weigh heavy objects or materials. They are typically used in industrial weighing applications where accurate measurements of weight are required.Floor scales are available in a wide range of sizes, capacities, and materials to suit different applications. They may be used to weigh items such as pallets, barrels, or large machinery components. Some floor scales are portable, while others may be permanently installed in a warehouse or manufacturing facility.

In industrial applications, floor scales are typically used to:

Monitor inventory levels: Floor scales can be used to weigh incoming and outgoing materials, allowing businesses to keep track of inventory levels and ensure that orders are fulfilled correctly.

Monitor production output: Floor scales can also be used to monitor the amount of material used in production processes, helping businesses to track production output and identify areas for improvement.

Ensure safety: Floor scales may be used to weigh heavy equipment or machinery components to ensure that they are within safe weight limits before they are moved or lifted.

Calculate shipping costs: For shipping and logistics companies, floor scales can be used to calculate shipping costs based on the weight of the items being shipped.

Overall, floor scales are a crucial tool for many industrial applications where accurate and reliable weight measurements are required. By using high-quality floor scales, businesses can improve efficiency, reduce waste, and ensure that their products meet industry standards.

Are the floor scales offered by METTLER TOLEDO legal for trade use?

Yes, METTLER TOLEDO offers floor scales that have OIML and NTEP approvals. Our legal-for-trade floor scales are rigorously tested and certified for use in industries where products are sold by weight. With legal-for-trade floor scales, you can conduct business transactions with confidence, knowing that your equipment performance is verified, transparent, and aligned with industry standards.

What types of industries benefit from using floor scales?

Industrial floor scales are large scales used for bulk weighing, logistics, and other manufacturing processes. METTLER TOLEDO floor scales and heavy-duty scales are suitable for industrial applications in a variety of industries including food, chemicals, pharmaceuticals, manufacturing, transportation & logistics, and more. Whether your process requires portability for flexible use, hygienic design for fast and easy cleaning, or rugged construction to accurately weigh heavy freight, METTLER TOLEDO has industrial floor scales for sale to meet your specific needs.

Can METTLER TOLEDO provide installation and calibration services for floor scales?

Yes, METTLER TOLEDO can provide installation and calibration services for floor scales. METTLER TOLEDO is a leading provider of weighing solutions and services, and we offer a range of installation and calibration services to ensure that floor scales are set up correctly and providing accurate measurements.

METTLER TOLEDO's installation services include onsite installation of the floor scale and any necessary accessories or hardware, as well as testing to ensure that the scale is functioning correctly. Our calibration services involve adjusting the scale to ensure that it is providing accurate measurements, and may include adjustments to the load cells, electronics, or other components of the scale.

In addition to installation and calibration services, METTLER TOLEDO also offers ongoing maintenance and support services to ensure that their customers' floor scales continue to function correctly over time. This may include regular calibration and testing, as well as repairs or replacements for any damaged or malfunctioning components.