Automated Precision Weigh Modules

Automated precision weigh modules deliver the highest levels of linearity, repeatability and speed for the needs of equipment, machine and instrument manufacturers. The compact designs and high accuracy of these sensors enable agility for even the most challenging automation applications and the tightest space requirements. Benefit from simple connectivity and comprehensive overload and wash-down protection to design systems that deliver reliable results in any production environment.

APW-Link™ Software

APW-Link™ software is an easy-to-use configuration tool for fast and comfortable commissioning and maintaining of high precision weigh modules. The software facilitates diagnostics, periodic calibration and allows storing of configuration data as backup and for duplication to other weigh modules for similar applications. Learn more and download. Read more

High Resolution Weighing

Machine and instrument manufacturers supplying the chemical, food and pharmaceutical industries need tailored weighing components to deliver fast, precise machines. Automated precision weigh modules (APW) from METTLER TOLEDO offer versatile mechanical, electrical and software features for easy integration to achieve these goals. Watch the video. Read more

Next Generation in Automated Weighing

With a width of only 25 mm (1 inch), fully integrated electronics and an Industrial Ethernet interface, the WMF weigh module can be used in most challenging applications with tightest space requirements where there is a need for quick and real-time date transmission to the PLC system. Integrate deeply within a machine or within glove boxes for easy cleaning. Watch the video. Read more

WXS High-Precision Weigh Modules

The flat design of WXS weigh modules enables analytical, high-precision weighing in industrial environments and automated laboratory conditions. Read more

PFK9 High-Precision Floor Scales

Floor weighing platforms for reliable, precise results and seamless PLC connectivity in demanding manufacturing environments Read more

WMF Slim High-Precision Weigh Modules

Compact WMF weigh modules with fully integrated Industrial Ethernet interface allow integration into real-time automation networks. Read more

WKC Mid-Range High-Precision Weigh Modules

WKC weigh modules offer a compact and cost-effective solution for on-board weighing in automated applications where high resolution is needed. Read more

SPC Compact High-Precision Weigh Sensor

The SPC compact weight sensor is tailored for fast weighing results in automated industrial applications where installation space is limited. Read more

Milligram Load Cells

Achieve precise weight measurements to the milligram with the highest levels of linearity, repeatability, and speed for the needs of equipment and machine manufacturers. Read more

Explore our Services - Tailored to Fit your Equipment

We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

Support & Repair

Maintenance & Optimization

Calibration & Quality

Training & Consulting

Professional Installation - Get it right from the start

FAQs

What is a weight sensor?

Weight sensor modules are tailor made at METTLER TOLEDO to meet the needs of equipment, machine and instrument manufacturers. Weight sensors play an important role in ensuring high precision weighing, and high precision load cells inside weigh modules that contain them offer the highest levels of linearity, repeatability and speed. We invite you to learn more about our high precision load cell technology and high precision load cell applications, as well as our ultra precision weight sensors.

Which weigh sensor is used in a weight-based machine? What sensor is used in weight scale?

METTLER TOLEDO offers precision load cells, high precision load cells and ultra precision load cell solutions that deliver several benefits depending on your machine or scale requirements. The compact size of a weight sensor and high accuracy load cell means it can be used in the most challenging and tightest space requirements. This can help ensure your high precision load cell applications have the highest accuracy. You will also benefit from comprehensive overload protection, which guards the high resolution load cell in the event of malfunction of handling devices or mistakes during installation. Wash-down protection, which can be activated by supplying air pressure, ensures an IP rating of IP65 and makes the weight sensor inside the ultra precision load cells eligible for cleaning operations with a water spray.

How does a weight sensor work? How do weight sensors work?

A weight sensor works by converting weight or a force that is applied against it into a signal. When a load is applied to a weight sensor, the resistance is changed, which leads to a change in output voltage. Whether your weight sensors are a precision load cell, a high precision load cell or an ultra precision load cell, see how METTLER TOLEDO weight sensors and milligram load cells can work for you. A fully integrated Ethernet interface and Ethernet TCIP/IP allow direct integration into a real-time automation network as well. Several weigh sensors also can be verified at any time with the internal calibration weight, which ensures correct functioning of the milligram load cell without stopping the application.

A high precision load cell featuring state-of-the-art weight sensor connectivity offers a compact and cost-effective solution for weighing in automated applications where high resolution and accuracy are needed. Learn more about our precision load cell, milligram load cell and high precision load cell options. Decide what load cell technology, load cell types and applications as well as load cell specifications suit to you.

What are the different types of sensors? What are the types of weight sensors?

METTLER TOLEDO has a wide variety of ultra precision load cells and milligram load cells, from high precision load cell solutions to precision load cell solutions – discover the ideal fit for your precision load cell or high precision load cell application today!

What is a high precision load cell / high accuracy load cell?

Precision load cell solutions are tailored to the needs of machine and equipment manufacturers for simple electrical and mechanical integration. The proven ruggedness of the milligram load cell inside the weight sensor allows reliable operation for many years in an industrial environment. Weight sensors are essential to optimizing milligram load cell performance. Weight sensors are typically used in a wide range of industries where precise measurements are required and are paramount to the success and reputation of the load cell company. These include pharmaceutical, manufacturing and automotive.

How to measure with a weight sensor?

Weight sensors are typically integrated into machines and connected to PLC systems. The measurement is completed by placing a load and using the weight signal for further processing.

What is the output of weight sensor?

Weight sensors deliver high-update weight signals, which are transmitted on digital, serial communication interfaces or Industrial Ethernet communication interfaces to PLC systems so that the measurement data can be used for further processing.

What is zero balance in weight sensor? What does it mean to zero a weight sensor?

The zero balance of a weight sensor is used to set the true zero of the scale when there is no load applied. The zero balance compensates for deviations on a weight sensor, which are typically caused by residual stress from overloading the load cell or repeated operations, to tell the system that there is no load, effectively calibrating the sensor to where the true zero output is.

Can weight sensors be repaired?

This depends on the sensor. In most cases, washdown units and wear parts can be exchanged or replaced but the sensors themselves cannot be repaired. Contact your local METTLER TOLEDO Service representative for help to determine the cause of the issue and the best approach to get your system up and running.

Do weight sensors wear out?

Weight sensors do not wear out, as long as they are used within the specified weighing range. Sealings can wear out if they are used in harsh environments, and these can be replaced; METTLER TOLEDO offers replacement for wear parts.

How do I know if my weight sensor is damaged?

If you do a calibration and the weight sensor is not accurate, you know it is damaged. Calibration services are offered by your local METTLER TOLEDO Service team, and they can help you to identify any potential damage and mitigate measurement risks.

How accurate are weight sensors?

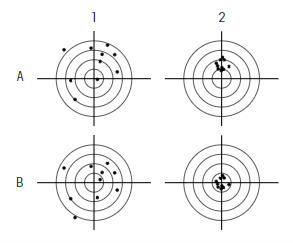

Accuracy is a combination of different deviations, such as repeatability and linearity. The diagram below helps us to define accuracy so that we can answer the question, “How accurate are weight sensors?

|

Row A shows measuring points with systematic error (lack of trueness); row B measuring points with no systematic error (correct). Column 1 shows scattered measurement points (lack of precision); column 2 shows measuring points with virtually no scatter (precise). For repeated measurements, accuracy requires correct and precise measuring points; thus, in general, only the measuring points in field B2 are accurate.

The most accurate weight sensor from METTLER TOLEDO is SPC with capacities up to 21 g, a readability of 0.01mg, repeatability of 0.02 mg, and linearity deviation less than 0.05 mg.