We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

Please choose your equipment type:

A melting point system is an analytical instrument used to determine the melting point of solid crystalline substances. At the melting point, there is a change in light transmission through the sample, which is automatically detected with METTLER TOLEDO Excellence Melting Point Systems. In addition to melting point, the versatile MP80 Excellence Melting Point System offers automatic determination of further physical properties, such as boiling point, cloud point, and slip melting point.

METTLER TOLEDO's Excellence Melting Point Systems offer many benefits to optimize and simplify your melting point analysis so that you complete measurements faster for higher throughput. Watch the video and learn more about our outstanding melting point instruments.

With simple operating routines and an intuitive touchscreen user interface, measurements can be performed quickly and easily. Just one click is needed to start the analysis, and the instrument does the rest, so you can attend to other important tasks while the measurement is being performed.

LabX™ PC software offers an all-around solution for laboratory data management. Connect your METTLER TOLEDO Excellence laboratory instrument to LabX and achieve data integrity and regulatory compliance.

With the METTLER TOLEDO melting point systems, full compliance with national and international standards, such as Ph.Eur. 2.2.14, USP <741>, ChP 0612, and JP 2.60, is ensured.

With the flexible MP80 Excellence Melting Point System you can measure melting, boiling, cloud and slip melting point fully automatically. Run multiple samples simultaneously and achieve maximum throughput and reliability.

Observing how a sample behaves at different temperatures can help characterize its physical properties. With the integrated video view measurements can be observed in real-time or replayed to verify your results.

You can count on us. Our Service Technicians and application experts are ready to support you to ensure maximum uptime, quality results and efficiency.

We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

Please choose your equipment type:

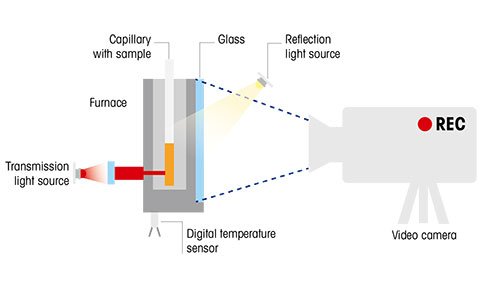

A digital melting point instrument uses a furnace and a video camera. The change in light transmission in relation to furnace temperature is measured for melting point detection. This melting point measurement is done digitally, reducing operator influence considerably. Up to 6 samples can be measured simultaneously with an accuracy down to 0.2 °C using short heating and cooling times. With its compact size, the METTLER TOLEDO melting point meter fits well on every lab bench.

A METTLER TOLEDO melting point system is represented in the schematic diagram below.

|

This system is a combination of a furnace and a video camera.

Melting point is determined by heating the sample. The furnace is used to control the temperature during an analysis. Temperature control and recording is performed by a digital platinum sensor.

The sample sits inside a glass capillary which is inserted into the furnace. During heating, when melting occurs, light transmission through the sample changes: when the material is solid and opaque, less light is transmitted through the substance. When a material is liquid and more transparent, more light is transmitted. This change in light transmission can easily be determined with a video camera, making this a reliable way to detect the melting point of a substance for a fully automatic melting point determination.

All results, measurement data, and video files are stored on the melting point device and a lab report can be generated fully automatically.

METTLER TOLEDO melting point instruments fully comply with most official standards for melting point determination, including:

For detailed information on Excellence Melting Point systems related to international norms and standards, visit www.mt.com/MPDP-norms

The Excellence Melting Point apparatus can be connected to METTLER TOLEDO's LabX laboratory PC software for analytical instruments and balances. This robust software powers the melting point system with automated data handling, high process security, and full SOP guidance.

LabX enables full integration of analytical data into other laboratory systems such as LIMS and ERP, which can help your lab comply with regulations and be ready for audits. LabX fully supports you with software validation and compliance, including 21CFR part 11, EU GMP annex 11 and ISO 17025.

All melting point instruments can also measure the melting range. The instrument models MP55 and MP80 can be used for diverse tasks. With the MP55, melting and slip melting points can be determined. On the MP80, the melting point application is extended by boiling point, cloud point, and slip melting point.

In detail, the METTLER TOLEDO MP55 and MP80 Melting Point Systems offer the possibility to perform the following applications:

Boiling Point Measurement:

The MP80 acts as an automatic boiling point apparatus according to the following measurement principle: to determine the boiling point, which is the temperature at which a phase transition from liquid to gas occurs, approximately 100 µL of sample is pipetted into a glass tube. A smaller boiling point capillary is then inserted into the filled tube to prevent superheating of the liquid, which would induce boiling retardation and give rise to inaccurate readings. The sample is then inserted into the boiling point instrument, and the method is started. The temperature rises, and gas bubbles are formed within the liquid and escape to the surface. These ascending bubbles reflect the light of the built-in light source and are detected individually. The frequency of the bubbles is measured and is used as the basis for boiling point determination. Ambient pressure is measured with a built-in calibrated barometer, and compensation to sea-level pressure is automatically calculated and applied to the results.

Cloud Point Measurement:

The MP80 acts as an automatic cloud point apparatus according to the following measurement principle: the cloud point of a solution corresponds with the temperature above which a sample becomes turbid. Cloud point determination is typically performed with a 1% weight dilution of the substance of interest in water. Approximately 100 µL of sample is pipetted into a glass tube and inserted into the cloud point tester. The solution of interest is transparent at the beginning of the experiment, and when the cloud point is reached, the solution becomes turbid. This turbidity is monitored via transmitted light detection – the higher the temperature above the cloud point, the more turbid the solution, and thus less light is transmitted through the solution. Automatic video camera detection of the decrease in transmitted light intensity is the key to obtaining repeatable and reliable cloud point results.

Slip Melting Point Measurement:

The MP55 and MP80 act as automatic instruments for slip melting point determination according to the following measurement principle: to determine the slip point of e.g. fats, oils, and waxes, an inner slip melting point capillary tube containing a column of sample is immersed in water, which is then heated at a specific rate. The temperature at which the column of fat is observed to start rising in the inner capillary tube – due to a combination of buoyancy and the molten outside surface of the column – is recorded as the slip melting point. The slip melting point of the substance is evaluated via digital image analysis. When the column of the substance starts to move upwards, the image processing algorithm determines the slip melting point fully automatically.